Nagy Zsák Kiürítő a JCN-től: Az innovatív megoldás nehéz anyagok kezeléséhez

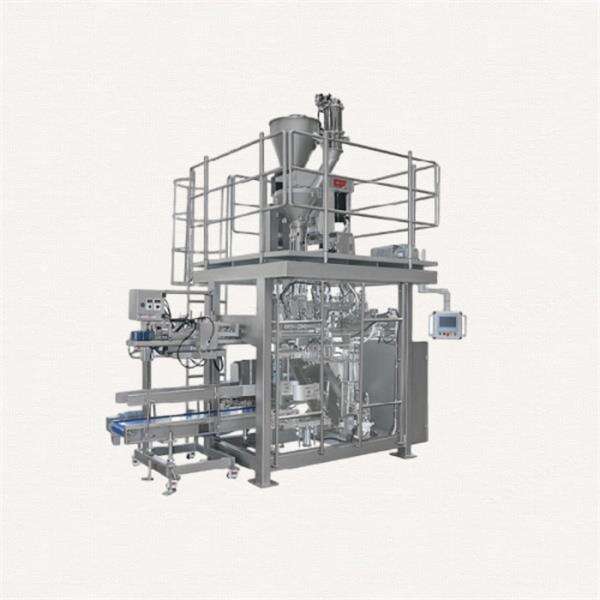

Jelenleg már elegük van a nehéz zsákokkal való küzdelemből és az anyagok kiürítésénél fellépő sérülésveszélyből? A Nagy Zsák Kiürítő olyan megoldás, amely segíthet ezekkel a kihívásokkal megbirkózni, például a JCN termékéhez hasonlóan automatikus Csomagoló Gép . Elmagyarázzuk, hogyan működik ez a berendezés, mik az előnyei, és hogyan használható biztonságosan.

A nagyzsák-osztó JCN által gyártott készülék, amely segít csökkenteni a kötelezettségeket az anyagok kezelése során, valamint a nagyzsák töltő gép a hagyományos zsákoktól eltérően, amelyekhez manuális kezelés szükséges, a nagyzsákokat egyszerűen felemelheti és behelyezheti az osztóba villás targoncával. Ez azt jelenti, hogy több zsákot tud kezelni rövidebb idő alatt, kisebb fizikai terheléssel, ami növelheti hatékonyságát és csökkentheti a balesetek kockázatát.

A nagyzsák-osztó egyre népszerűbbé vált számos iparágban, az élelmiszer- és gyógyszeripartól a vegyi anyagokon és ásványokon át, például a JCN JCN-nek nevezett terméke esetében is automatikus csomagoló gép . Tartozik hozzá egy keret, egy emelőberendezés, egy töltőnyílás és egy ürítőszelep. Az emelőberendezés lehetővé teszi a zsák felemelését és rögzítését a keretben csavarokkal. A töltőnyílás csatlakoztatható egy adagolóedényhez vagy szállítószalaghoz, miközben az ürítőszelep segítségével szabályozható az anyagok mozgatása.

A nagyzsák-osztó használata jelentősen csökkentheti a nehéz zsákok kezeléséből eredő sérülések kockázatát, például vízszintes táplálékkeverő amit a JCN fejlesztett ki. Ugyanakkor fontos megfelelően használni a berendezést a balesetek elkerülése érdekében. Az alábbiakban néhány biztonsági szempontot sorolunk fel, amelyekre érdemes figyelni:

- Mindig viseljen megfelelő személyi védőfelszerelést, mint például kesztyűt és védőszemüveget.

- Győződjön meg arról, hogy az emelőberendezés biztonságosan csatlakozik a zsákhoz, mielőtt felemelné.

- Ellenőrizze a zsákot sérülésekre vagy szivárgásokra, mielőtt behelyezné az osztóba.

- Tartsa be a gyártó utasításait a töltőnyílás és az ürítőszelep csatlakoztatásával kapcsolatban.

- Soha ne maradjon egy olyan eset alatt, amelyet felemelnek vagy leengednek.

- Amikor az eszközt nem használják, mindig kapcsolja ki az áramellátásról.

A JCN egy gyártóvállalat, amely Nantong városában, a jiangsu tartományban foglal el 30 000 négyzetméternyi területet. A vállalat az elmúlt évek során egyik legnagyobb cégként nőtt fel, amely fejleszti, mérnöki szempontból tervezi, gyártja és forgalmazza a legújabb porkezelő berendezéseket. Szem előtt tartjuk az ügyfeleknek nyújtott érték elérésének elvét, amelyet gyors kommunikáció kialakításával, aktív nagy zsákos ürítőberendezésekkel és folyamatos magatartásunk javításával érünk el.

A JCN tanúsítvánnyal rendelkezik az ISO 9001:2015 szabvány szerint, CE-tanúsítvánnyal és nagy zsákos ürítőberendezésre szóló használati minta szabadalmi igazolvánnyal is. Termékeinket teljes egészében saját gyárunkban gyártjuk, összeszereljük és teszteljük szállításuk előtt. Az ügyfelek számára lehetőségük van termékeink ellenőrzésére annak biztosítására, hogy megfelelnek igényeiknek.

A JCN vállalkozás a nagy zsákos ürítőberendezésekre és a porkezelő berendezésekre, valamint az ezzel kapcsolatos technológiákra specializálódott. Jelenleg legnépszerűbb termékeink a keverők, zsákok ürítőrendszerei, sziták, ipari mérlegek, automatikus zsákoló és robotos palettázó rendszerek, amelyeket széles körben alkalmaznak az élelmiszeriparban, az új anyagok gyártásában, valamint a gyógyszeriparban, és jó hírnévre tettek szert. Olyan cég vagyunk, amely komolyan veszi ügyfelei számára nyújtott professzionális megoldásokat, mélyen megértve ügyfeleink igényeit.

a JCN kutatás-fejlesztési tevékenységét az élelmiszer-csomagolásra specializált nagy zsákos ürítőberendezésekre irányítja. Fejlesztettük a csomagolótechnológia javított változatát, amelyet más országokból importáltunk. 24 órás online szolgáltatást kínálunk: bármilyen kérdése van a gép kezelésével kapcsolatban, egyszerűen lépjen velünk kapcsolatba.

A Big Bag kiürítő könnyen kezelhető berendezés, mindazonáltal szükséges némi előkészítés a kiürítési folyamat megkezdése előtt, ugyanúgy, mint a JCN esetében. zsáktöltő berendezések az alábbiakban bemutatjuk, hogyan kell használni egy nagy zsák kiürítőt:

1. Készítse elő a kiürítőt: Győződjön meg arról, hogy a berendezés megfelelően indítva van, és minden szükséges alkatrész a helyén van. Ellenőrizze a felemelő rendszert, fogókat és a kiengedő szelepet sérülések szempontjából.

2. Emelje fel a zsákot: Használjon nagy kapacitású targoncát vagy más emelőeszközt a zsák felemeléséhez a keretbe. Ellenőrizze, hogy a zsák középen legyen és biztonságosan rögzítve van-e az emelőrendszerhez.

3. Csatlakoztassa a töltőnyílást: Miután a zsák elhelyezve van, csatlakoztassa a töltőnyílást a szállítószalaghoz vagy adagolóhoz.

4. Nyissa ki a leeresztő szelepet: Állítsa be a kioldó szelepet a szükséges áramlási sebességnek megfelelően. Indítsa el a szállítót vagy a tölőtartályt, és figyelje a anyagmozgatást.

5. Távolítsa el a zsákot: Miután a zsák kiürült, zárja le a kioldó szelepet, és válassza le a töltőnyílást. Használjon targoncát az üres zsák keretről való eltávolításához.

A nagyzsák-osztók tartósak és minimális karbantartást igényelnek, például a JCN gyártmányai. tömeges zsákürítő állomás ugyanakkor elengedhetetlen a gyártó utasításainak követése a berendezés ellenőrzésére, tisztítására és kenésére vonatkozóan. A rendszeres karbantartás meghosszabbíthatja a berendezés élettartamát, és biztosíthatja az optimális teljesítményt.

Nagyzsák-osztó kiválasztásakor válasszon megbízható beszállítót, aki minőségi felszerelést kínál, mint például a JCN termékei vízszintes mixer . Keressen olyan tanúsítványokat és garanciákat, amelyek a berendezés tartósságát, megbízhatóságát és biztonságát garantálják. Ne áldozza fel a minőséget a költségtakarékosság érdekében, mivel az alacsony minőségű felszerelés balesetekhez, leállásokhoz és hatékonyságvesztéshez vezethet.