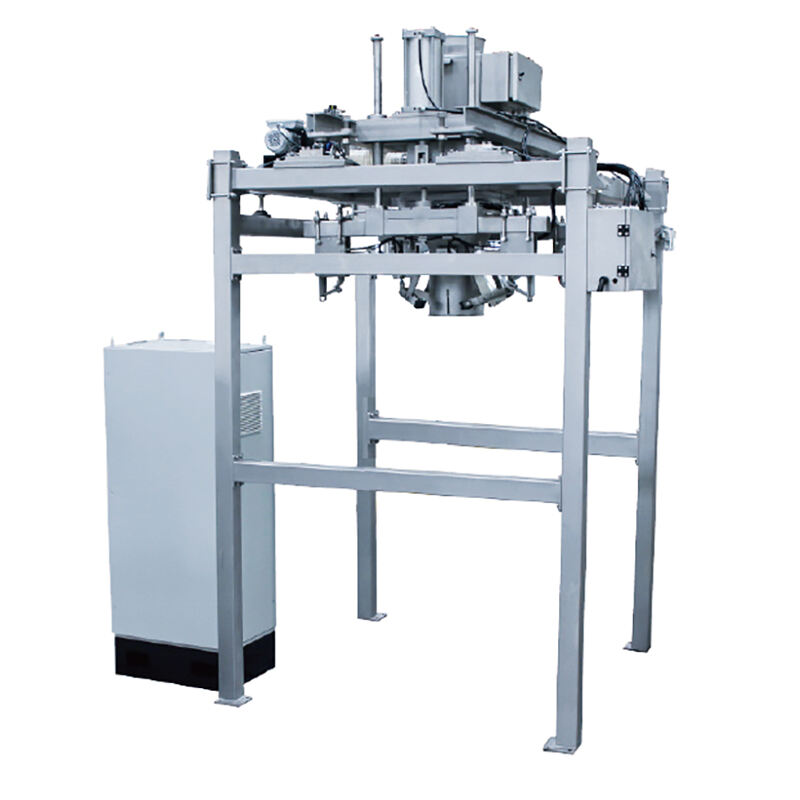

Automatický stroj na váženie prášku v oceliarskom priemysle

Automatický stroj na váženie prášku je však požehnaním pre určité položky, ako je cukor alebo múka. Možno jednou z najzaujímavejších vlastností tohto stroja je skutočnosť, že šetrí ešte viac času. Zatiaľ čo tento proces by inak mohol byť pomerne časovo náročný, ak by ste napríklad museli stokrát odvážiť pevnú látku – pri väčšine sušených práškov by to trvalo veľmi dlho – stroj ponúka kvalitné benefity. Automatické miešanie samo osebe ušetrí peniaze, pretože nie je potrebný človek na ručné váženie. Navyše dávkovanie strojom na porcie zníži chybovú medzeru a zabezpečí presnosť a správnosť váh.

Inovatívne techniky s automatickými strojmi na váženie prášku

Zavedenie automatického stroja na váženie prášku v odvetví wagging bolo veľkým krokom smerom k inovácii. Hoci táto zmena bola prelomová, zjednodušila proces, urobila ho surový a rýchlejší bez straty hmotnosti pre obe osoby manipulujúce s práškovými látkami. Zároveň zvýšila prevádzkovú efektívnosť znížením výpadkov a plytvaním zdrojmi. Tento stroj je určený na presnosť, okamžite ušetrí silné a tuhé priemyselné výrobné linky od ľudskej neschopnosti a tiež zníži odpad.

Ďalej, pri používaní akéhokoľvek nástroja je bezpečnosť kľúčová a to neplatí iba pre automatický stroj na váženie prášku. V prípade preťaženia motora alebo jeho prehriatia sa systém Wet/Dry/Blow Poll automaticky vypne, aby sa predišlo nehode. Zároveň obsahuje bezpečnostný systém interlocku, čo zaisťuje extrémne bezpečné plnenie prášku do vážiaceho stroja.

Funkcia automatického váženia prášku – Krok jeden) Chceme, aby ste sa uistili, že je stroj zapojený a následne zapnutý – Krok dva) Potom nalejte svoj prášok dovnútra, ale dávajte pozor na množstvo, ktoré vkladáte, pretože príliš veľa prášku sa zovrie a nebude správne fungovať. Následne zadajte požadovanú hmotnosť na ovládacom paneli stroja a stlačte toto tlačidlo na spustenie váženia. Zariadenie Vám poskytne presnú hmotnosť prášku a akonáhle dosiahne požadované množstvo, samo sa zastaví.

Slovom povedané, kvalita automatického váženia prášku. Čím vyšší je výrobný proces a technický obsah zariadenia výrobcu, tým presnejšie sú výhody v presnosti výroby. – Lepšie je to urobené. Vyššia kvalita strojov má zvyčajne aj lepšie meno a to preto, že produkty sú testované. O výrobcoch sa dozviete, keď si skontrolujete ich recenzie online alebo sa len opýtate niekoľkých priateľov, ktorí už predtým používali kufre, no tu opäť väčšinu vecí dokážete spraviť sami. Dĺžka času, počas ktorého vydrží bez porúch, menej dielov potrebných na opravu niečoho a to, ako ľahké je o stroj starostlivo sa starať, tiež určujú, či ste zakúpili kvalitný stroj.

Sú určené pre presné stroje na váženie práškov a môžu byť inštalované rovnakým spôsobom do každého spracovateľského závodu vrátane malých podnikov, ako je pekárenský priemysel, farmaceutický alebo chemický priemysel. Vážené, kombinované a balené zložky sa spracovávajú pomocou automatizovaných alebo poloautomatických strojov, ktoré sú nevyhnutné. Dobrou vlastnosťou týchto mlynkov je, že dokážu zomlieť výrobky na hrubú aj jemnú textúru, a preto sú nevyhnutné pre potravinársky priemysel.

Ako bolo uvedené vyššie, automatický stroj na váženie práškov je povinný pre priemysly ako sú farmaceutické. Nie len, že šetrí čas a eliminuje odpad, zvyšuje produktivitu, ale je tiež jednoduchý na používanie a údržbu s integrovanou bezpečnosťou používateľa a ergonómiou. Na skutočne maximálne využitie tohto stroja je dobré investovať do automatického zariadenia na smršťovacie balenie od významného výrobcu.

Podniková činnosť JCN zahŕňa výrobu zariadení na manipuláciu s práškami, ako aj príslušnú technológiu. Naše hlavné výrobky v súčasnosti pozostávajú z systémov na vyprázdňovanie vreciek, miešania, váženia a automatického balenia do vreciek, ako aj robotických systémov na paletizáciu, ktoré sa široko používajú v potravinárskom priemysle, pri výrobe nových materiálov a v farmaceutickom priemysle. Získali sme vynikajúci automatický vážiaci stroj na prášky. Sme podnik zameraný na poskytovanie profesionálnych riešení pre našich zákazníkov na základe hlbokého pochopenia ich potrieb.

JCN má výrobnú továreň s rozlohou 3000 štvorcových metrov nachádzajúcu sa v meste Nantong v provincii Jiangsu. Spoločnosť JCN sa vyvinula na jednu z najvýznamnejších spoločností, ktoré navrhujú automatické vážiace stroje na prášky, vyrábajú ich a poskytujú najmodernejšie zariadenia na manipuláciu s materiálmi.

"JCN sa zameriava na výskum a vývoj vybavenia na balenie potravín. Vyvinuli sme vylepšené technológie balicích strojov, ktoré boli pôžičané z iných krajín. Sme dostupní po celý deň, preto ak máte akékoľvek otázky týkajúce sa automatického vážiaceho stroja na prášok alebo jeho prevádzky, neváhajte nás kontaktovať."

JCN získal certifikáciu ISO 9001:2015, rovnako ako certifikáciu CE a množstvo certifikátov užitočných patentov. Všetky naše výrobky sú vyrábané výlučne v našej továrni. Pred dodaním sú zostavené a otestované. Zákazníkom je tiež vítané osobné príchod na kontrolu, aby sa uistili, že zodpovedajú vašim požiadavkám na automatický vážiaci stroj na prášok.