Amazing; Auger Filler For Powder: Quality and Safety 8

Do you want a fast and accurate way to measure, dispense powders? So, why not just use good old auger fillers. They are known as hand tools, which make miniature powder into it very easily with perfect accuracy />} Overview of Auger Fillers - A Comprehensive GuideAugmented Reality is taking over the future like no one would ever think.

Advantages of Auger Fillers

Auger fillers are certainly a game changer when it comes to powder measuring. These advantages can allow you to zip through your own milk powder filling jobs. Here are some benefits of auger fillers for you to examine it better.

Precise Filling: Among the best feature auger fillers can offer is a high degree of accuracy powder fills. Weight and volume monitoring weigh heavily on how sharpened filling operations are managed, something only auger fillers can do instead of allowing a given amount before shutting down.

Consistence : Auger filing device can fill consistant all over the time, so it is well documented evidence for this. This means that you could know, without a doubt, exactly how precise and accurate each fill would be with every single use - regardless of how many times.

Fast Fill Times: We get the best possible speeds with auger fillers. Suited to high throughput packaging ops where time counts, the tools are particularly agile in filling containers on-the-go

Simple to preserve- Auger fillers are made in a way that they fulfil the essentials. The filler is parts with better time and will be having less maintenance required making it sustainable for you to afford the answers.

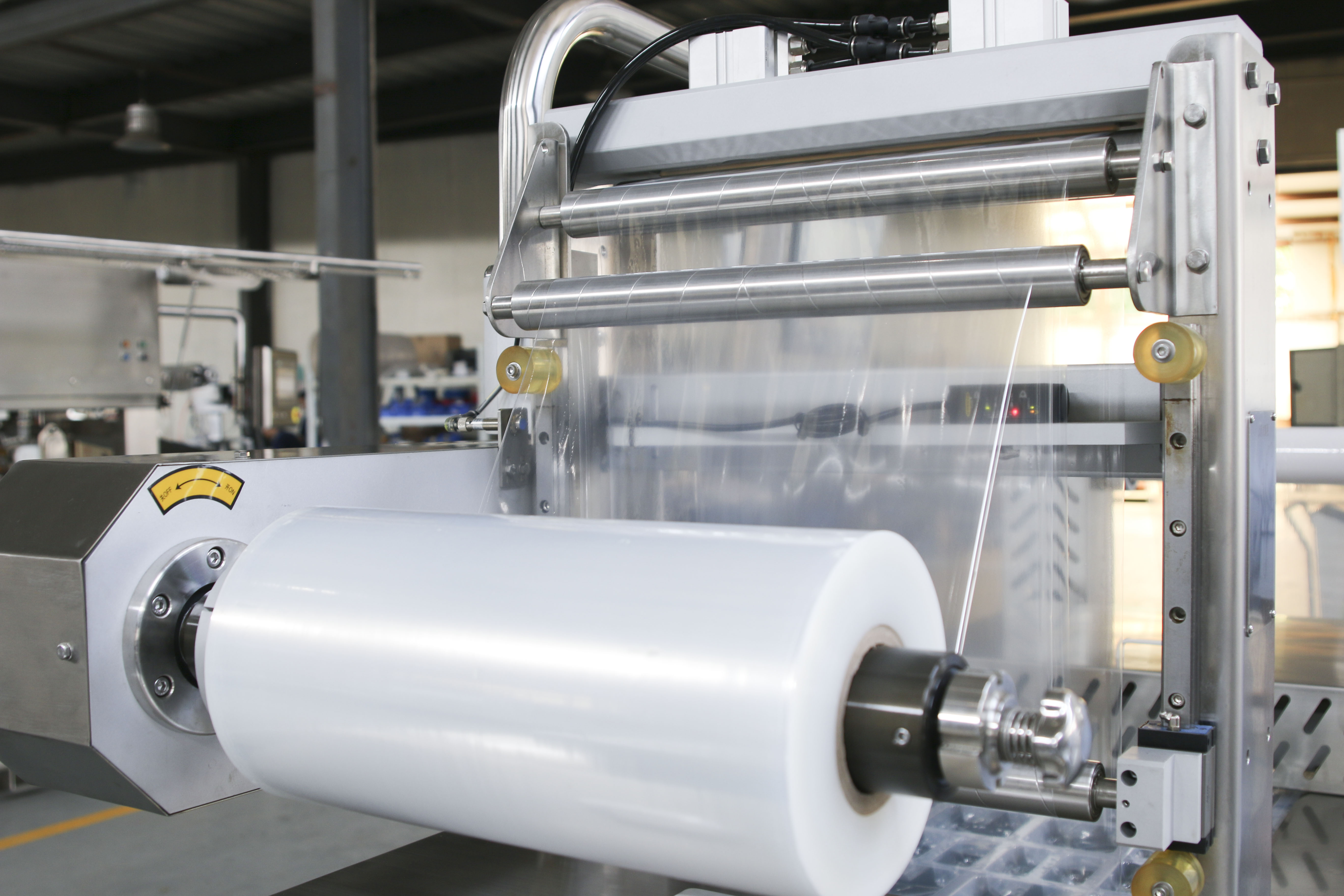

Due to the swift evolution in technology, it almost appears that there is ever-in-progress change going on within this auger fillers world. As a result, automation is one of the advances that has stemmed from this, and auger fillers using electronic systems for improved control have also sprung up.

Whatever the equipment may be, safety is important in all its operations and auger fillers aren't an exception. Fillers made to the best safety standards and have been through rigorous testing stages of consumption in many fields, so you can use: Food industry Pharmaceuticals sector Chemical products

The Most Common Application of Auger Fillers

A hand auger filler might sound incredibly complicated, but it is quite simple once you walk through the steps of how to use an auger. The steps include:

Clean Your Machine: make sure that this device is clean and ready to use before you fill. Place enough powder in the hopper Print Calibration cube

Powder Pouring: Now, by gently pour the powder in a manner that it is leveled and settle down inside so how to fill right accurately.

Fill Cycle: The fill cycle may be initiated after the powder filling machine successfully dispenses a consistent powder dose. Stop when the container is full!

Dab on the Container- Dab half of container and close it securely. Keep churning until you get the powder

The brand reputation for quality and service should be taken into consideration when selecting an auger filler Do not choose products that have no guarantee, nor any store support service or technical team to help you if necessary

An auger filler adapts well in firmly pressing, semi-liquid or watery applications for prescription drugs and chemicals. They are great for anything you want to package dry like flour, milk powder, protein powder or coffee/spices. They are also used in filling of medical capsules, pesticidal bottles and cosmetic jars for different market requirements.

DescriptionOnly put, the versatile auger filler is actually unchallenged if you need to fill powder solution securely along with quickly and also accurately. Auger fillers are the birth of powder filling because it offers a wider list of benefits, innovative solutions and commitment to healthness as well as functionality.

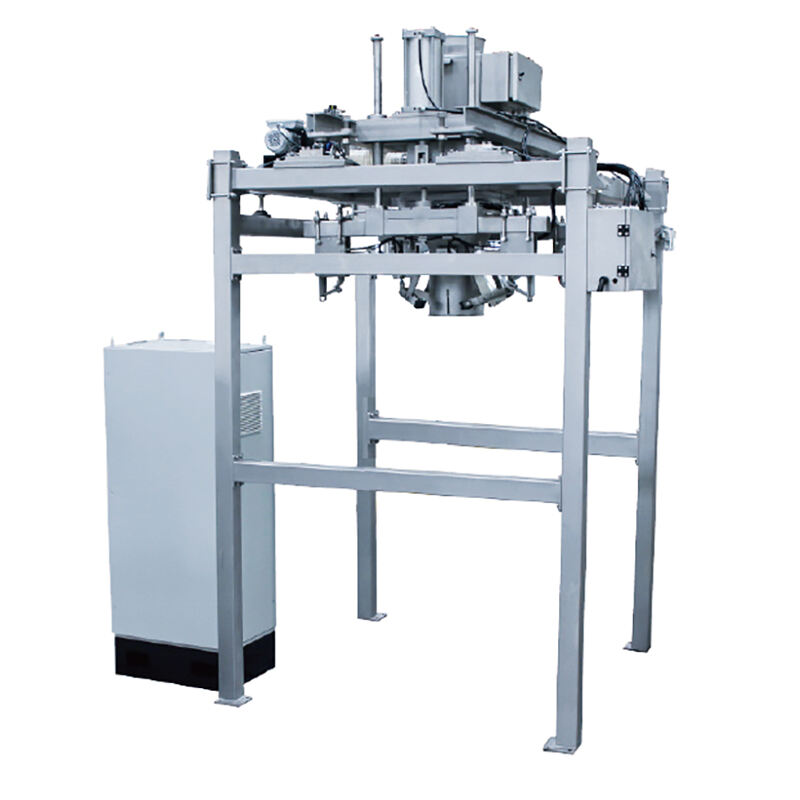

JCN business involves manufacturing equipment for handling powder and technology.principal products include bag dumping ,sieving, mixing,industrial weighing, auto bagging robotic palletising auger filler for powderwhich is widely used in food, new materials and pharmaceutical industries and has earned an enviable reputation.We a company deicated to provide professional solutions to our customers by gaining an a thorough understanding of their needs.

"JCN concentrates R and D of food packaging equipment. have developed and auger filler for powderpackaging machinery technologies imported from abroad. "are accessible 24/7 online, so if you have any queries about operation your machine, please don't hesitate to contact us."

JCN has received CE certificates as well as ISO 9001:2015 auger filler for powder. All of our products, assembled and tested before shipping, are created 100% in our factory. The customer can also request an inspection to make sure that they will meet your expectations.

JCN a manufacturing that occupies an area of 30,000 square metres Nantong city,Jiangsu province.And it has grown auger filler for powderone of the leading company which designs, engineer production distribution of high-tech powder material handling equipment.We constantly adhere to the notion of creating value our clients by establishing quick communication, active collaboration and constantly improving our methods of conduct.