- Description

Description:

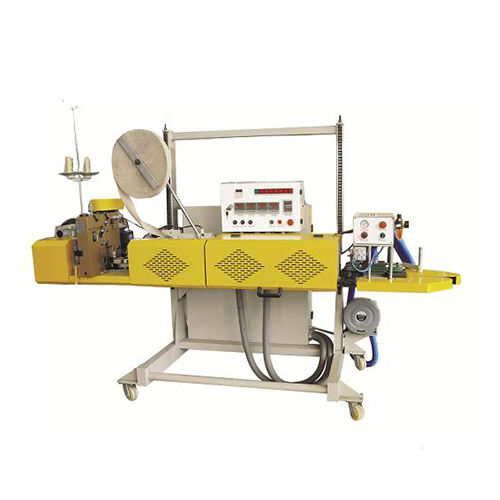

JBF-Z series automatic heavy-duty plastic bags sealing performance quality, and efficient, continuous seal thick PE or PP plastic bags, and paper-plastic composite bags, plastic bags; Can auto complete the process of bag mouth dust removal (Optional), trimming, sewing, tape over-wrapping, heating, pressing and counting.

Applications:

Multi-layer paper bag, Paper PE compound bag, AL-PE inner liner bag or PE bag. etc. Widely used in chemical, pharmaceutical, food industries products bag closing and sealing.

Specifications:

| Model | JBF-ZB |

| Sealing speed | 7-10m/min |

| Machine height to ground | 800-1700mm adjustable |

| Packaging product to bag mouth distance | Min 250mm |

| Air pressure | 0.6Mpa |

| Transmission power | 0.75kw |

| Heating temperature | 0~400℃ |

| Sewing power | 0.4kw |

| Bag mouth cleaning power | 1.5KW(option) |

| Heating power | 6kw |

| Air consumption | 3.5NL/min |

(*) The melting point of the outer bag is 140℃-150℃, and the melting point of the inner bag is 100℃ (the temperature difference between the inner and outer bags is 30-50℃ or more).

Competitive Advantage:

1. Easy to install and simple to maintain.

2. Suitable for various bag specifications.

3. Various models are availbe for different types of bag heating and closing.

4. This unit uses a controller, motor frequency conversion speed controller, and heating system detection device to form the main body of the control system to achieve coordinated control of the entire heat sealing machine.

EN

EN

AR

AR

FR

FR

DE

DE

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

VI

VI

TH

TH

TR

TR

MS

MS

HR

HR

DA

DA

NL

NL

FI

FI

EL

EL

HI

HI

IT

IT

NO

NO

PL

PL

SV

SV

IW

IW

LV

LV

SR

SR

SK

SK

SL

SL

UK

UK

HU

HU

MT

MT

FA

FA

AF

AF

IS

IS

MK

MK

AZ

AZ

MN

MN

UZ

UZ