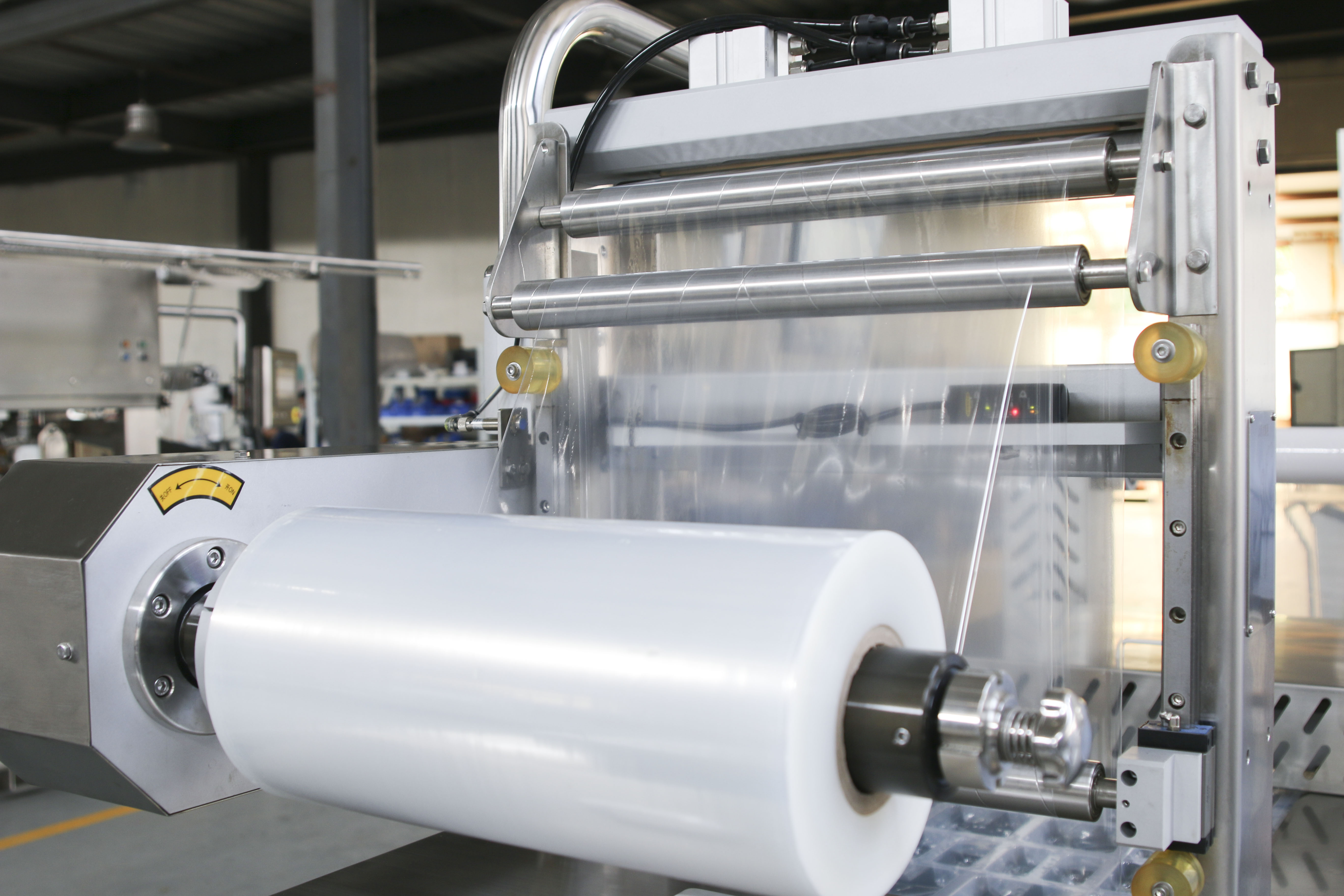

We recognize at JCN the necessity of improving production methods, making them efficient as possible. One method by which we achieve this is through use of Thermoforming Packing Machine, and packaging devices. These devices are created to accomplish work swiftly and precisely with less personnel and their potential errors. Through the automation of the filling and packaging we increase the ration per time unit and hence we are able to satisfy the customers’ requests and gardtime.

Our high-tech filling and packaging lines are all equipped with the latest technology to optimise speed and precision in our production. These machines are able to fill and package items far more quickly than by hand, meaning we can hit short deadlines and fulfil orders in bulk. Not only are they precise and reliable, but they allow us to produce products of the highest quality consistency which we are proud to deliver to our customers who count on our name.

One of the other uses provided by a flexible filling and packing machine involves improved product display. This equipment is engineered to accommodate a variety of types or styles of packaging, we need to be able to tailor the look of our goods to a variety of tastes and changes in the marketplace. No matter if we have to pack products in boxes, bottles, or pouches, our filling and packing machines can meet the demand of packaging, and our products differ from those on the markets, also we can get much more clients.

Besides efficiency and product appearance, the ease to use is another consideration when selecting the filling and packaging equipment. The filling machines are user friendly easy to use machines with minimal training required for our staff to operate and clean. This simple design is not just easy for our operators to learn in a short time, it’s also less likely of an operator error during the production process. Then, all these packing processes can provide a smooth, interrupted process.

One of the most beneficial features of high-speed filling and packaging machines is the ability to produce the most volume with the least amount of waste. These types of machines allow us to package in a more timely manner, as many times faster than manual which means our capacity is greater and we can produce a higher quantity of products in less time. Not only does this higher output enable us to better fulfill our clients’ requirements, it also minimises the risk of over-production, and consequently, waste. Through waste-cutting and output-boosting, we can increase our overall profit margin and sustainability as a business.

JCN has received CE certificates as well as ISO 9001:2015 filling and packaging machine. All of our products, assembled and tested before shipping, are created 100% in our factory. The customer can also request an inspection to make sure that they will meet your expectations.

JCN has filling and packaging machineplant which covers 30000 square meters Nantong, Jiangsu Province. has grown to be one of leading companies that design engineers, manufactures, distributes the latest powder handling equipment.

"JCN focused on R and D of food packaging equipment. have improved and filling and packaging machinepackaging machinery technology brought from world. We are 24 hours online assistance, you have any questions about machine operation please feel free get in touch with us."

JCN business involves manufacturing powder handling equipment as well as technology.Our main products currently comprise bag dumping, mixing, weighting, auto bagging, robotic palletising system that has been extensively used the food, new material as well as pharmaceutical industry, have earned an excellent filling and packaging machine.We are a business committed providing professional solutions for our customers based on an in-depth understanding of customer's needs.